For decades, Formula One has been dubbed the “fastest R&D lab on Earth”. The notion was that motor racing technology would sooner or later trickle down to the road car world. While that was certainly the case for some innovations and inventions, it was not necessarily true on a large scale. The challenges of Formula One were often too specific or the cost for industrial-scale production too high to introduce certain technologies in production vehicles. This, however, has changed in recent years.

Since the introduction of full hybrid powertrains, F1 technology has become more relevant for road cars than it has ever been before. But it is also true for other parts of the car – especially in the world of bits and bytes. Here is the fifth of five reasons, presented by Mercedes, why now, more than ever before, Formula One is at the forefront of technology – from road cars to consumer electronics, from medical technology to smart cities.

The fourth industrial revolution – transforming production technologies

Digitalisation does not only change the design of F1 cars and their development. They also change the way of production. For a long time, the production of road cars and F1 cars were very different disciplines. While the former were produced on a large, industrial scale with a limited amount of customisation, the latter were manufactured in a highly customised process. Production costs also played a role. Carbon fibre, for example, was never a cheap material. But the costs are lower if you only use it on two cars. Using carbon fibre in a mass production road car, however, was for many years too expensive. That is why the material appeared in F1 in the 1980s but did not make it into series production until many years later.

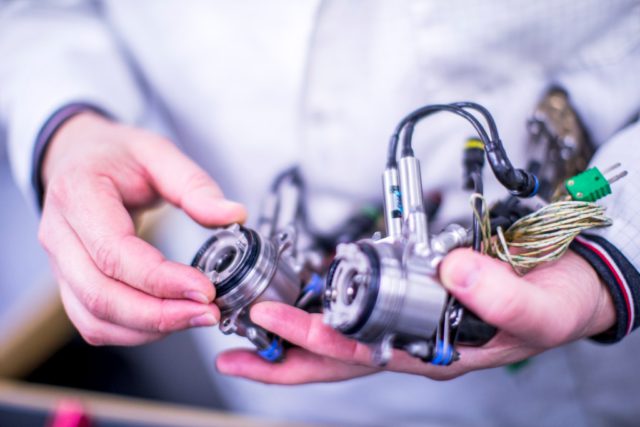

With the rise of modern production methods, this gap between large-scale production and highly customised manufacturing has grown much smaller. This world is in the middle of the fourth industrial revolution and Formula One is at the forefront of it. Technological advancements in the world of connectivity and data processing mean that modern production tools live in the physical world as much as they live in the virtual world. While production machines used to be only good at automation – doing the same task over and over again – modern machines become increasingly good at doing different tasks. They can build complex shapes, using a number of materials and are able to adapt to change. Technologies like additive layer manufacturing mean that you could potentially one day see machines that build car components one day and a pacemaker the next.

Formula One teams are comparatively small organisations, but they build a lot of different parts

An F1 car is basically a prototype that sees the introduction of new parts on a weekly basis. So the teams have to be able to not just develop, but also manufacture parts as quickly as possible. It’s precisely this kind of experience with modern production methods that makes Formula One interesting for a company like Daimler. Road car production is becoming increasingly complex with different models being manufactured on the same production line and more and more choices for customers to individualise their cars. So today’s world of Formula One is a perfect environment for testing tomorrow’s road car production methods on a smaller scale.