Volkswagen is driving the transition to e-mobility with a consistency and commitment unlike that of virtually any other automaker. As part of the ELECTRIC FOR ALL campaign, the brand will be putting attractive models at affordable prices on the road. This way the company will pave the way for the breakthrough of electric vehicles. The electric offensive is based on the modular electric drive matrix (MEB), a technology platform developed specifically for electric vehicles.

Production of the Volkswagen ID. will begin in Zwickau at the end of 2019

This will be the world’s first vehicle based on the MEB.

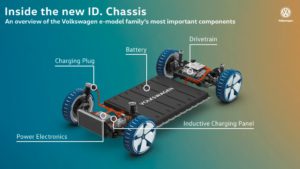

At the launch of the ELECTRIC FOR ALL campaign, the company gives media representatives the opportunity for a first deep insight into the technological basis of the ID. That happens at a media workshop in the Gläserne Manufaktur in Dresden. There Volkswagen is demonstrating the centrepiece of the MEB. It is the rolling chassis without the bodywork and interior. In that exact form, it will be in use in series models. Volkswagen is also seizing the initiative when it comes to charging infrastructure. In Dresden happens the premiere of the design prototype of the “Volks-Wallbox”. This Wallbox is an affordable home system that makes charging the ID. family easy and convenient.

ELECTRIC FOR ALL stands for the Volkswagen brand’s vision and central promise. That is to make innovative technologies accessible to as many customers as possible. The MEB is the key to the “electric car for all”. It enables a hitherto unachievable price-service ratio. The campaign will be also instrumental in transforming the electric vehicle from a niche product into a bestseller.

MEB: the technological platform for the electric age

The systematic platform strategy is one of Volkswagen’s unique selling propositions. It testifies to the power the brand and the Group are investing in e-mobility. Some 10 million vehicles across the Group will be based on this platform in the first wave alone.

As Christian Senger, Head of the E-mobility Product Line, explained, the MEB platform brings significant benefits for customers.

The MEB will make it possible to install larger batteries, for example. That alone significantly enhances the range. “The car holds the road really well thanks to the flat battery situated in the floorpan and the space inside is much more generous. We are making substantial headway with the sense of spaciousness.”

Furthermore, the MEB bundles Volkswagen’s entire production knowledge

It is not a platform for vehicles with combustion engines that went through retroactive modification. From the outset, it has been to be 100 per cent electric. By the end of 2022, four Group brands will be ramping up 27 MEB models worldwide.

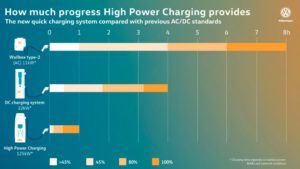

All members of the ID. family are designed for fast charging. Using fast charging systems, the battery can be charged 80 per cent in about 30 minutes. That is possible thanks to a completely new battery system. It is developed by Volkswagen Group Components and is significantly more powerful.

ID. family: e-mobility made in Germany

In every respect, the Volkswagen ID. will be an electric car made in Germany. Most of the Volkswagen locations in Germany participate in the development and production of the first MEB-based electric cars. These include the Volkswagen Group Components sites in Braunschweig, Salzgitter and Kassel. The company is investing €1.3 billion of a total €6 billion at these three sites.

Wolfsburg

The ID. was conceived and developed by the E-mobility Product Line and Research and Development units at the main plant in Wolfsburg. This is also where the production of the pre-series model is currently taking place. It will subsequently undergo tests at the Ehra-Lessien proving grounds.

Zwickau and Dresden

Volkswagen will be building the series production models of the ID. family in Saxony. It is investing €1.2 billion in Zwickau. Rhe plant will become the first pure-play MEB factory as well as the largest competence centre for e-mobility in Europe. Meanwhile, the Gläserne Manufaktur began building the Volkswagen e-Golf1 back in April 2017. The plant is evolving into a “Centre of Future Mobility”.

Braunschweig

The Braunschweig plant will manufacture the battery system. This factory with a long history already builds the batteries for the e-up!2, the e-Golf and the Passat GTE3 plug-in hybrid. Braunschweig is today the battery and packaging specialist. The plant has extensive know-how in power electronics as well as battery cooling systems and software management. After an expansion, it will build up to half a million battery systems per year in future.

Salzgitter

The plant starts pre-series production of rotors and stators for the MEB this year.

Kassel

The Kassel plant has been the competence centre for electric drives for many years. Production of the entirely new MEB drive begins at the end of this year. The site is the lead plant for high-quality, cost-efficient electric motors.